- 模板介绍

- 下载记录

- 用户评价

东芝e-STUDIO230_232_280_282维修手册中文版

服务手册

多功能数码复印机

e-STUDIO230/232/280/282

有关 e-STUDIO230/232/280/282 系列的安装维护服务的总体注意

事项

必须由合格的维修技术人员进行安装与维护。

1) 运输 / 安装

- 在搬动或安装多功能数码复印机时,应由两个人按图中所示位置进行。

复印机相当重,大约有 75 公斤 (165.34lb.),因此在搬运时要全神贯注,特别小心。

- 在搬运复印机时,不要使多功能数码复印机的活动部件或单元受力(例如控制面板, ADU 或

RADF)。

- 必须使用交流 110V/13.2A,115V 或 127V/12A,220-240V 或 240V/8A 的电源专用插座。

- 为了安全,多功能数码复印机必须接地。

- 选择适当的地方安装多功能数码复印机。应避免安装在过热、高湿、多灰、有振动或阳光直射之

处。

- 因为多功能数码复印机会放出少量臭氧,应为其提供有适当通风的操作环境。

- 为保证复印工作人员时有充足的操作空间,多功能数码复印机左侧至少应保持 80cm(32'') 的无障

碍空间,右侧也至少保持 80cm(32'') 的无障碍空间,背后应至少保持 10cm(4'') 的空隙。

- 电源插座应安装在多功能数码复印机旁边,并应便于工作人员使用。

- 确保安全安装电源线,使其周围没有缠绕物。

05/

英文缩写说明

e-STUDIO520/600/720/853.10.5 改变复印速度3-53 AD ................................... 模数转换

ADF .................................... 自动输稿器

ADU ................................... 自动双面器

APS ................................... 自动纸型选择

AMS ................................... 自动倍率选择

APC .................................... 自动电源控制

API ................................... 应用程序接口

BYPASS ................................... 旁路(手动供纸)

CCD ................................... 电荷耦合器/ 光电转换器

CM ................................... 纸盒组件(本书中指MY-1021)

CODEC .................................... 编码解玛器

DDNS .................................... 动态域名服务

DF ................................... 输稿器

DARM ................................... 动态随机存储器

DPI ................................... 点/ 英寸

Firmware ................................... 固化程序

FQDN ................................... 完全合格域名

HPF ................................... 高通滤波器

HVPS ................................... 高压板

HSYNC ...................................(激光单元)水平同步检测

IGBT .................................... 绝缘栅双极性晶体管

I/F .................................... 接口

IPC ....................................(复印机与整理器之间)接口板

IVSYNC ................................... 图象垂直同步

LDAP .................................. 轻量目录存取协议

LCD .................................... 液晶显示屏

LED .................................... 发光二极管

LSI ................................... 大规模集成电路

LSU ................................... 激光单元

LVDS .................................... 低电压差分信号

LVPS ................................... 低压电源板

NCP .................................................................Netware 核心协议

NDS .................................................................Netware 目录服务

NVRAM .................................... 非易失性随机访问存储器

MIB .................................... 管理信息基础系统

MIME .................................... 多用途网际邮件扩充协议

PLL ................................... 相位锁定环路

PM .................................... 定期保养

PFP .................................... 供纸工作台

PWM ................................... 脉冲宽度调制

RADF ................................... 翻转(双面)自动输稿器

RFC .................................. 请求注解

RTC .................................. 实时时钟

SFB ................................... 旁路(手送)供纸

SLP ................................... 服务定位协议

SNMP .................................... 简单网络管理协议

SRAM .................................. 静态随机存储器

SRP .................................. 装订器

WINS ...............................................................Windows 网名服务

1. 规格/ 附件/ 选购件/ 耗材.............................................................................................. 1-1

1.1 规格..................................................................................................................................... 1-1

1.2 附件..................................................................................................................................... 1-6

1.3 选购件.................................................................................................................................. 1-7

1.3.1 e-STUDIO230/230L/280/280S ................................................................................. 1-7

1.3.2 e-STUDIO232/232S/282/282S................................................................................. 1-8

1.4 耗材..................................................................................................................................... 1-9

1.4.1 e-STUDIO230/230L/280/280S ................................................................................. 1-9

1.4.2 e-STUDIO232/232S/282/282S................................................................................. 1-9

1.5 系统列表............................................................................................................................ 1-10

1.5.1 e-STUDIO230/230L/280/280S ............................................................................... 1-10

1.5.2 e-STUDIO232/232S/282/282S............................................................................... 1-15

2. 错误代码和自诊模式...................................................................................................... 2-1

2.1 错误代码列表....................................................................................................................... 2-1

2.1.1 卡纸.......................................................................................................................... 2-1

2.1.2 维修请求................................................................................................................... 2-5

2.1.3 互联网传真/ 扫描功能错误....................................................................................... 2-8

2.1.4 打印功能错误.......................................................................................................... 2-16

2.2 自诊模式............................................................................................................................ 2-18

2.2.1 输入检查(测试模式 03)...................................................................................... 2-20

2.2.2 输出检查(测试模式 03)...................................................................................... 2-31

2.2.3 测试打印模式(测试模式 04)............................................................................... 2-34

2.2.4 调整模式(05)...................................................................................................... 2-35

2.2.5 设置模式(08)...................................................................................................... 2-65

2.2.6 像素计数器........................................................................................................... 2-193

2.2.7 调整模式(05) / 设置模式(08)分类列表....................................................... 2-202

3. 调整................................................................................................................................ 3-1

3.1 自动墨粉传感器调整............................................................................................................ 3-1

3.2 图像尺寸调整....................................................................................................................... 3-3

3.2.1 概述.......................................................................................................................... 3-3

3.2.2 在定位辊处的纸张定位............................................................................................. 3-5

3.2.3 与打印相关的调整..................................................................................................... 3-7

3.2.4 与扫描相关的调整................................................................................................... 3-12

3.3 图像质量调整(复印功能)................................................................................................ 3-21

3.3.1 浓度调整................................................................................................................. 3-21

3.3.2 Gamma 斜率调整................................................................................................... 3-22

3.3.3 锐度调整................................................................................................................. 3-23

3.3.4 设定范围校正.......................................................................................................... 3-24

3.3.5 设定范围校正(背景峰值调整)............................................................................. 3-24

3.3.6 脏污/ 模糊文本调整................................................................................................ 3-25

3.3.7 Gamma 平衡调整< e-STUDIO 232/282 > ............................................................. 3-25

3.3.8 图像浓度调整.......................................................................................................... 3-26

3.4 图像质量调整(打印功能)................................................................................................ 3-27

3.4.1 脏污/ 模糊文本调整................................................................................................ 3-27

3.4.2 图像浓度调整.......................................................................................................... 3-28

3.5 图像质量调整(扫描功能)................................................................................................ 3-29

3.5.1 浓度调整................................................................................................................. 3-29

3.5.2 锐度调整................................................................................................................. 3-30

3.5.3 设定范围校正.......................................................................................................... 3-31

3.5.4 设定范围校正(背景峰值调整)............................................................................. 3-32

3.5.5 设定范围校正(文本峰值调整)............................................................................. 3-32

3.6 高压变压器调整................................................................................................................. 3-33

3.6.1 调整........................................................................................................................ 3-33

3.6.2 注意........................................................................................................................ 3-39

3.7 扫描部分的调整................................................................................................................. 3-41

3.7.1 扫描架..................................................................................................................... 3-41

3.7.2 透镜单元................................................................................................................. 3-46

3.8 供纸系统的调整................................................................................................................. 3-49

3.8.1 供纸导致的纸张横向偏移........................................................................................ 3-49

3.9 显影单元的调整................................................................................................................. 3-50

3.9.1 磁穗刮刀至磁辊的间隙........................................................................................... 3-50

3.10 RADF 调整 (MR-3016)....................................................................................................... 3-53

3.10.1 RADF 位置调整...................................................................................................... 3-53

3.10.2 RADF 高度调整...................................................................................................... 3-57

3.10.3 偏斜调整................................................................................................................. 3-59

3.10.4 传感器的自动调整和 EEPROM 的初始化............................................................... 3-61

3.10.5 定位调整................................................................................................................. 3-62

3.10.6 反转时的定位调整................................................................................................... 3-63

3.10.7 反转电磁铁调整...................................................................................................... 3-64

3.10.8 RADF 开/ 合开关调整............................................................................................ 3-66

3.10.9 RADF 开/ 关传感器调整......................................................................................... 3-67

3.10.10托盘容量调整......................................................................................................... 3-68

3.11 RADF 调整 (MR-3020)....................................................................................................... 3-69

3.11.1 RADF 位置调整...................................................................................................... 3-69

3.11.2 RADF 高度调整...................................................................................................... 3-74

3.11.3 偏斜调整................................................................................................................. 3-76

3.11.4 前端位置调整.......................................................................................................... 3-79

3.11.5 水平位置调整.......................................................................................................... 3-80

3.11.6 复印倍率调整.......................................................................................................... 3-82

3.11.7 RADF 开/ 关传感器调整......................................................................................... 3-83

3.12 整理器调整(MJ-1022).................................................................................................... 3-84

3.12.1 调整推纸板宽度...................................................................................................... 3-84

3.12.2 调整推纸板的角度................................................................................................... 3-86

3.12.3 传感器档片重叠位置的调整.................................................................................... 3-87

3.12.4 纸叠处理电机皮带张力的调整................................................................................. 3-88

3.12.5 释放纸叠托盘导杆固定片........................................................................................ 3-90

3.12.6 上托盘角度调整...................................................................................................... 3-91

3.12.7 DIP 开关功能.......................................................................................................... 3-93

3.13 整理器调整(MJ-1025).................................................................................................... 3-95

3.13.1 调整折叠位置(电气系统(整理器/ 脊缝式单元))............................................. 3-95

3.13.2 传感器输出调整(电气系统(打孔单元;选购件))............................................. 3-96

3.13.3 注册打孔数(电气系统(打孔单元;选购件)).................................................... 3-97

3.13.4 更换 EEP-ROM (IC1002) 后(电气系统(打孔单元;选购件))......................... 3-98

3.14 钥匙复印计数器(MU-8, MU-10)..................................................................................... 3-99

4. 定期维护........................................................................................................................ 4-1

4.1 定期维护支持模式................................................................................................................ 4-1

4.1.1 概述.......................................................................................................................... 4-1

4.1.2 操作流程和操作屏幕................................................................................................. 4-1

4.1.3 部件更换的工作流程................................................................................................. 4-6

4.2 定期维护步骤概述................................................................................................................ 4-7

4.3 检查操作项目....................................................................................................................... 4-8

4.4 定期维护检查表................................................................................................................... 4-9

4.5 定期维护套件..................................................................................................................... 4-25

4.6 夹具表................................................................................................................................ 4-26

4.7 润滑脂表............................................................................................................................ 4-27

4.8 耗材保存与处理注意事项................................................................................................... 4-28

4.8.1 保存 TOSHIBA 耗材的注意事项............................................................................. 4-28

4.8.2 感光鼓的检查与清洁............................................................................................... 4-29

4.8.3 鼓清洁刮板与转印带清洁刮板的检查与清洁........................................................... 4-30

4.8.4 定影辊与压力辊的检查与清洁................................................................................. 4-30

4.8.5 清洁辊的检查与更换............................................................................................... 4-30

5. 故障排除........................................................................................................................ 5-1

5.1 与各错误代码有关的诊断与处理方法................................................................................... 5-1

5.1.1 输送卡纸................................................................................................................... 5-1

5.1.2 卡纸........................................................................................................................ 5-15

5.1.3 盖板打开卡纸.......................................................................................................... 5-22

5.1.4 输送卡纸 (RADF).................................................................................................... 5-28

5.1.5 整理器卡纸............................................................................................................. 5-35

5.1.6 与驱动系统相关的维修请求.................................................................................... 5-47

5.1.7 与供纸系统相关的维修请求.................................................................................... 5-48

5.1.8 与扫描系统相关的维修请求.................................................................................... 5-54

5.1.9 与定影单元相关的维修请求.................................................................................... 5-56

5.1.10 与通信相关的维修请求........................................................................................... 5-58

5.1.11 与 RADF (MR-3016) 相关的维修请求..................................................................... 5-59

5.1.12 与 RADF (MR-3020) 相关的维修请求..................................................................... 5-60

5.1.13 与激光单元相关的维修请求.................................................................................... 5-60

5.1.14 与整理器相关的维修请求........................................................................................ 5-61

5.1.15 其它维修请求.......................................................................................................... 5-76

5.1.16 互联网传真/ 扫描功能错误..................................................................................... 5-79

5.2 图像故障排除..................................................................................................................... 5-94

5.3 更换线路板和 HDD .......................................................................................................... 5-116

5.3.1 更换 HDD ............................................................................................................. 5-116

5.3.2 更换 SYS 板......................................................................................................... 5-119

5.3.3 当安装了数据清除套件(GP-1050/1060)时的注意事项.................................... 5-120

5.3.4 HDD 信息显示...................................................................................................... 5-121

6. FIRMWARE 更新........................................................................................................... 6-1

6.1 通过下载夹具更新 Firmware (e-STUDIO230/280)............................................................... 6-2

6.1.1 PWA-DWNLD-350-JIG2 (48 MB) ............................................................................. 6-4

6.1.2 PWA-DWNLD-350-JIG1 (16 MB) ........................................................................... 6-11

6.1.3 将数据写入下载夹具 (PWA-DWNLD-350-JIG) ....................................................... 6-20

6.1.4 K-PWA-DLM-320.................................................................................................... 6-21

6.2 通过下载夹具更新 Firmware (e-STUDIO232/282)............................................................. 6-31

6.2.1 PWA-DWNLD-350-JIG2 (48 MB) ........................................................................... 6-33

6.2.2 将数据写入下载夹具 (PWA-DWNLD-350-JIG) ....................................................... 6-42

6.2.3 K-PWA-DLM-320.................................................................................................... 6-44

6.3 用 FSMS (场地维修管理系统)对 Firmware 进行更新(e-STUDIO230/280) ................... 6-54

6.4 用 USB 存储装置进行 Firmware 更新 (e-STUDIO230/280)............................................... 6-66

6.5 用 USB 存储装置进行 Firmware 更新 (e-STUDIO232/282)............................................... 6-79

6.6 附录................................................................................................................................... 6-93

6.6.1 e-STUDIO230/280.................................................................................................. 6-93

6.6.2 e-STUDIO232/282.................................................................................................. 6-94

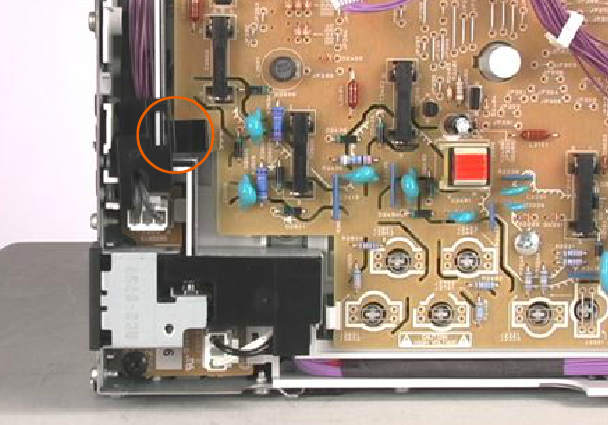

7. 电源单元........................................................................................................................ 7-1

7.1 输出通道.............................................................................................................................. 7-1

7.2 保险丝.................................................................................................................................. 7-3

7.3 电源单元配置....................................................................................................................... 7-4

8. 远程维修........................................................................................................................ 8-1

8.1 自动耗材订单....................................................................................................................... 8-1

8.1.1 概述.......................................................................................................................... 8-1

8.1.2 项目设置................................................................................................................... 8-2

8.1.3 设置步骤................................................................................................................... 8-5

8.1.4 订单格式................................................................................................................. 8-12

8.2 维修通知............................................................................................................................ 8-14

8.2.1 概述........................................................................................................................ 8-14

8.2.2 设置........................................................................................................................ 8-14

8.2.3 要通知的项目.......................................................................................................... 8-18

9. 采用 USB 存储装置进行数据克隆 (e-STUDIO232/282)................................................. 9-1

10. 线束连接图................................................................................................................... 10-1

10.1 交流线束............................................................................................................................ 10-1

10.2 直流线束(e-STUDIO230/230L/280/280S)..................................................................... 附录

10.3 连接器列表(e-STUDIO230/230L/280/280S)................................................................. 附录

10.4 直流线束(e-STUDIO232/282)....................................................................................... 附录

10.5 连接器列表(e-STUDIO232/282).................................................................................... 附录

1. 规格/ 附件/ 选购件/ 耗材

2. 错误代码和自诊模式

3. 调整

4. 定期维护

5. 故障排除

6. FIRMWARE 更新

7. 电源单元

8. 远程维修

9. 采用 USB 存储装置进行数据克隆 (e-

STUDIO232/282)

10. 线束连接图